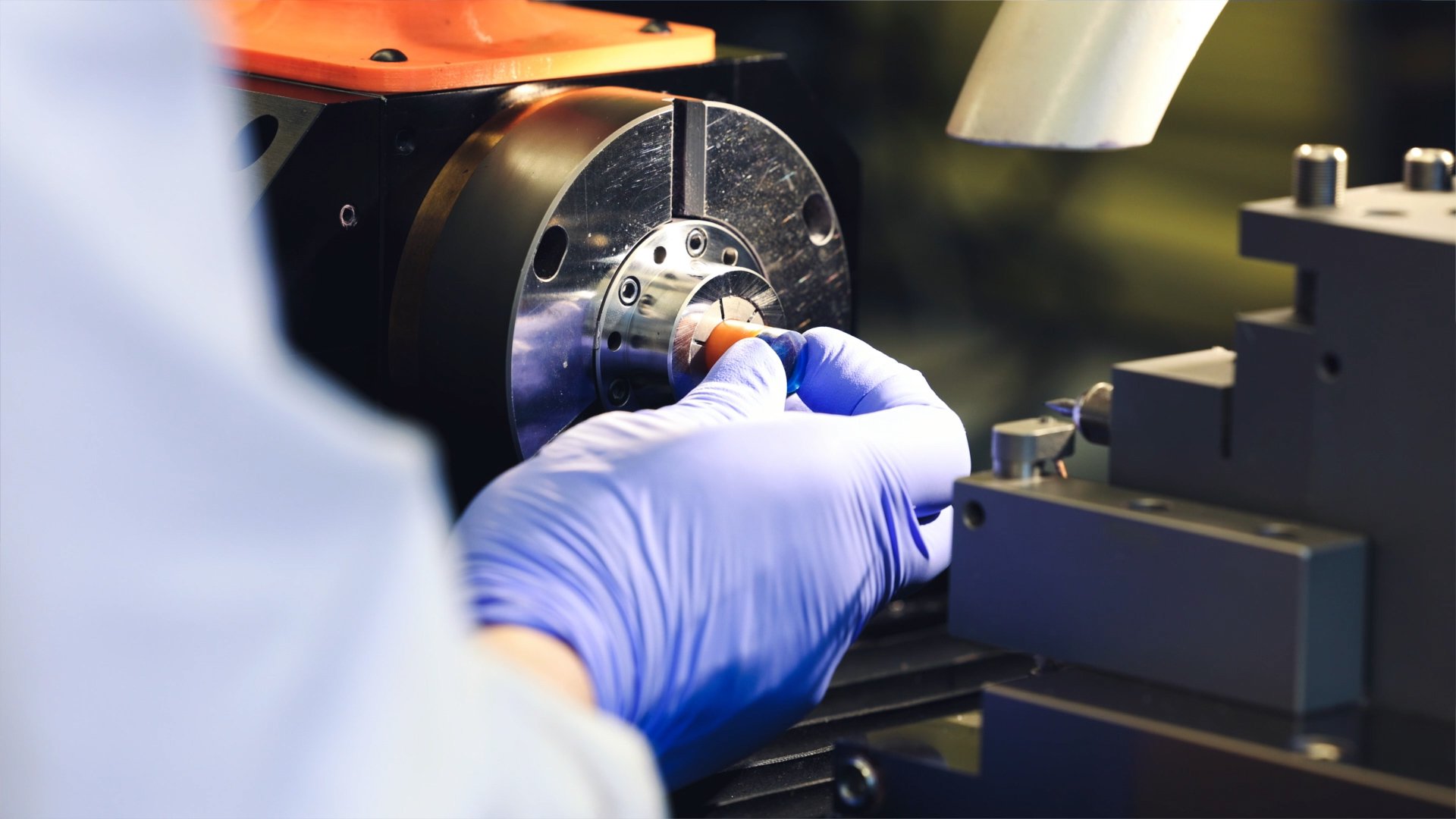

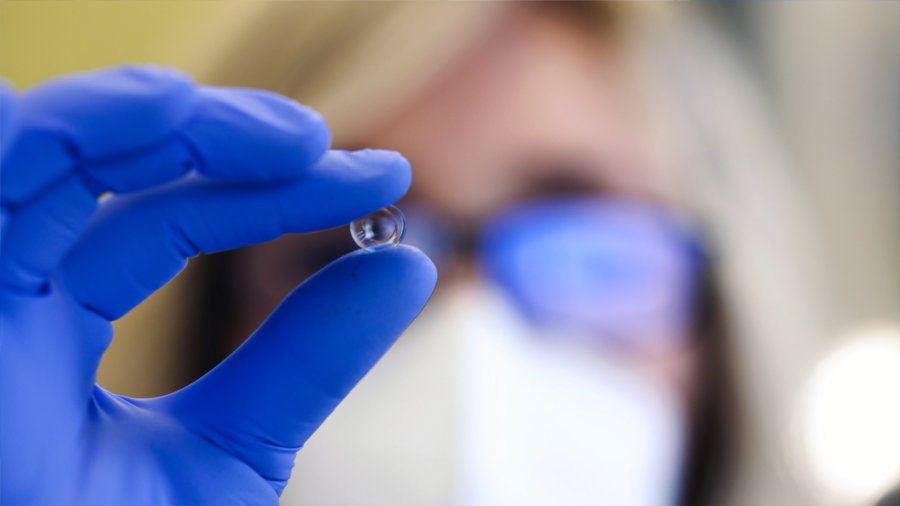

The tip of the lathe approaches the blue cylinder and begins to mold its shape. Layer after layer, with a precision of a few millionths of a millimetre, the button - as the polymer used as a raw material is called by the technicians - gradually becomes a contact lens. From the laboratory in via IV Novembre in Gardolo (TN) only "unique pieces" come out, modeled with the latest generation technologies on the shape of the eyes of individual customers. We are at Imago Contact, one of the few companies in the world capable of designing and manufacturing custom contact lenses that are highly innovative and capable of solving complex visual problems. A real Trentino excellence, which has decided to rely, during its growth path, on the economic, logistic and scientific aids that the area makes available to its companies, especially those that stand out for their innovative charge.

Imago Contact: a 126-year history

No, we are not joking. The history of Imago Contact has its roots in 1897, when Gottardini Optics was founded in Trento. Always family-run, it has been a point of reference in the Trentino main city for over a century. At the beginning of the 2000s came the turning point: the brothers Maurizio and Tiziano Gottardini, tired of searching the market in vain for contact lenses that met the quality and reliability criteria they needed, decided to become manufacturers themselves. In 2006, they therefore started collaborating with an Italian laboratory that was already producing contact lenses and, together, they founded Imago Contact. The goals were ambitious: to study and realise advanced designs for solving complex visual problems and to produce high-performance and safe lenses. In 2013, the Trentino part of Imago Contact acquired full ownership of the company and started an autonomous growth process.

The help from Trentino

Being born in Trentino was not a secondary factor in the company's growth. In fact, in the first years of its life, Imago Contact was able to benefit from various types of assistance:

- Economic-financial: Trentino Sviluppo provided the company with the necessary resources to buy the first lathe and finance the R&D phase

- Expertise: the company was able to rely on the competence of researchers from the Department of Industrial Engineering at the University of Trento, who made a fundamental contribution in the study phase of materials for the production of the innovative FOOT (Optimised Wavefront Lens)

- Logistics: the company began studying new materials and geometries in Trentino Sviluppo's BIC in Pergine, where it remained until 2012. It then moved to the Gardolo site, where it expanded its production department

The new production line and the ERDF notice 1/2022

You know, to grow you have to keep investing in technology and innovation. With 3 permanent employees (in addition to two directors), external collaborators in the medical and engineering sectors, and a market that was beginning to grow, in 2022 Imago Contact therefore decided to take a further step forward and create a new, highly innovative, semi-automated production line. Part of the funds needed to realise the project came from the Autonomous Province of Trento through the ERDF Notice 1/2022, which provided a total plafond of around 5.5 million for innovation in the production processes of Trentino companies.

Thanks to the financing (155 thousand euro out of a total investment of 512 thousand euro), the company was able to purchase state-of-the-art machinery and benefit from business consultancy that revolutionised the way the entire production and sales cycle was conceived. The creation of the new semi-automatic line will allow the company to increase its production capacity, activate business scalability and expand its markets, reaching as far as abroad.

The production stages of a custom-made contact lens

1. Realisation of the optometric design by the optical centre

2. Transmission of the order in digital format to the laboratory

3. Construction laboratory:

- the optometric design is processed by software and translated into a language understandable by the lathe

- lathe turning and polishing of the inside and outside of the lens

- chemical disinfection for RGP lenses

- steam sterilisation by autoclave for soft lenses

- packaging

All Imago Contact products, which are distributed in Italy directly and exclusively to optical centres, are classified as Medical Devices and have certification and CE marking issued by one of Europe's largest certification organisations.